Another method to cast a part is by using plaster molds.

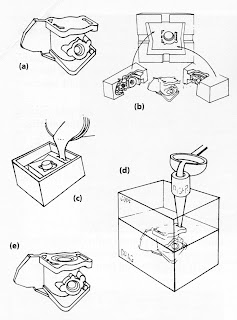

Another method to cast a part is by using plaster molds.Plaster slurry is poured onto the cope and drag pattern halves and allowed to set.

The mold is then removed from the patterns, baked to remove moisture, and assembled.

The metal is poured into the resultant cavity. Finally, the mold is broken to remove the casting.

Procedure Properties:

advantages:

- short lead time, superior surface quality, thin wall or section.

- Intricate parts, minimum or no draft angle (except for pattern removal).

- Plaster molds limited to nonferrous metals.

- Limited in size, not good for heavy sections.

- Precision parts, often used to prototype for die-casting.

- Sculpture, jewelry.

Manufacturing Methods: Metal (liquid state) Forming 02_Investment Casting

Manufacturing Methods: Metal Forming 01_Sand Molding + Sand Casting

No comments:

Post a Comment